3 Most Common Semi-Truck Air Brake Issues

When it comes to the safe operation of semi-trucks, understanding air brake systems and the potential issues that may arise is crucial for drivers and fleet managers alike. Air brakes play an essential role in ensuring that large vehicles can slow down and stop effectively, especially under heavy loads or challenging driving conditions. Recognizing and addressing the most common semi-truck air brake issues not only enhances safety on the road but also contributes to the longevity of the vehicles and reduces maintenance costs. Due to the sheer size and weight of semi-trucks, even minor brake malfunctions can escalate into serious hazards, making it imperative for industry professionals to stay informed about these vital systems.

Strange Noises and Vibrations

Strange noises and vibrations emanating from the air brake system can signal underlying problems that require immediate attention. Such sounds might include grinding, hissing, or squeaking, which could indicate worn-out brake components, such as pads or drums, or air leaks within the system. Vibrations often point to imbalances or misalignments in the brake assembly, potentially compromising the effectiveness of braking performance. Ignoring these warning signs can lead to increased wear on the brake system and can ultimately result in brake failure, posing severe safety risks for both the driver and other road users. Regular inspections and maintenance routines are essential to identify and rectify these issues before they escalate into more significant problems.

Fading and Locking

Fading and locking are serious issues that can occur within a semi-truck’s air brake system, often resulting from overheating or excessive wear. Fading typically manifests when brake performance diminishes after continuous use, such as during lengthy downhill descents, which can lead to insufficient stopping power and increased stopping distances. On the other hand, locking occurs when a brake becomes stuck in the engaged position, preventing normal operation and potentially leading to tire damage or loss of control. Drivers must monitor the performance of their air brakes and conduct regular checks to ensure that air pressure levels are appropriate and that all components are functioning correctly.

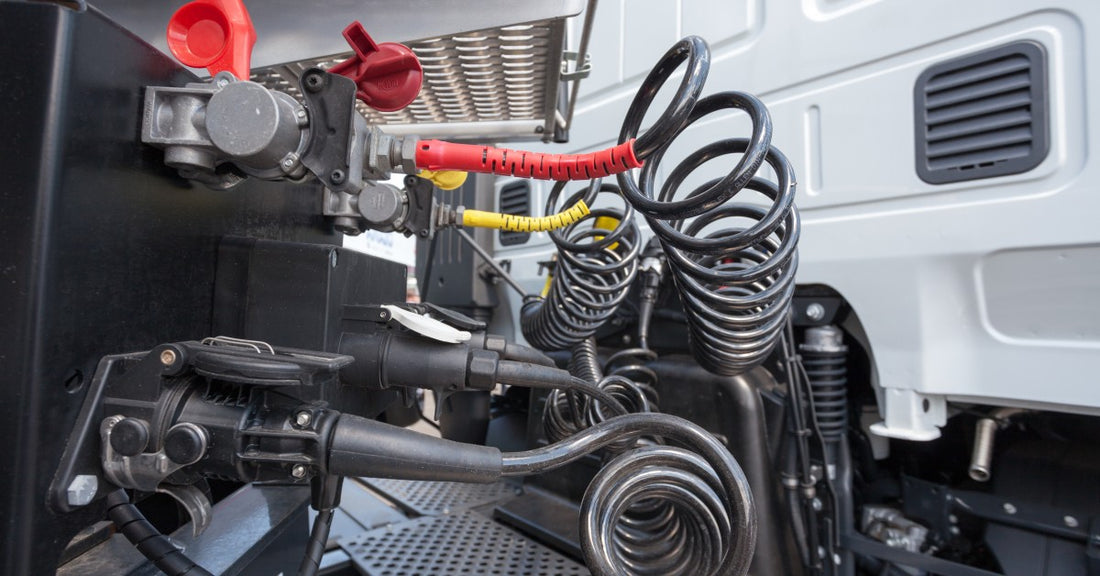

Leaks and Air Pressure Loss

Leaks and air pressure loss in a semi-truck’s air brake system are critical issues that can lead to catastrophic braking failures if not addressed promptly. Air leaks can occur in various parts of the system, including hoses, connections, or the brake chamber itself, resulting in a drop in air pressure that compromises the system’s overall effectiveness. Drivers may notice signs of air pressure loss through reduced brake responsiveness or warning lights indicating low pressure. Regular inspections and maintenance of the air brake components are essential to identify and repair any leaks, thereby maintaining optimal brake performance. Fleet managers and drivers need to be vigilant about monitoring air pressure levels, as even small leaks can escalate into significant problems, endangering safety on the road and notably increasing repair costs.

Understanding the most common semi-truck air brake issues is crucial for maintaining the safety and reliability of these large vehicles. Regular inspections, routine maintenance, and prompt identification and repair of any problems are essential for preventing minor issues from escalating into more severe hazards. Source quality truck air brake system parts from Van Horn Truck Parts to stay out of the shop and on the road!