Air Brake Overview: What Do the Treadle and Foot Valve Do?

Air brakes are essential components in modern heavy-duty vehicles, ensuring effective and reliable braking performance. At the heart of the air brake system are the treadle and foot valves, which are crucial for regulating and controlling the flow of compressed air through the system. Read on for a comprehensive overview of air brake systems and what the treadle and foot valves do. We’ll also offer some tips for troubleshooting performance issues.

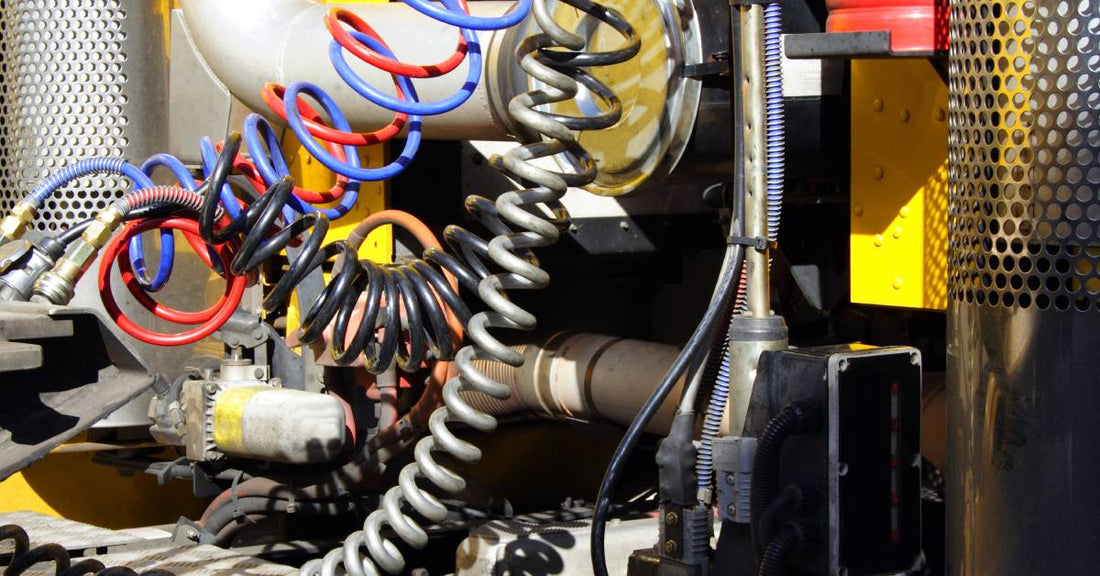

Understanding the Importance of Air Brake Systems

Compared to hydraulic braking systems commonly used in smaller vehicles, air brakes offer the durability and reliability required for trucks carrying heavy loads over long distances. The air brake system’s design allows for quick and powerful application, which is essential for stopping large vehicles efficiently and safely and preventing accidents. Furthermore, the fail-safe nature of air brakes, which engage in the event of air pressure loss, adds layers of safety, ensuring trucks remain stationary if braking power is compromised.

Beyond their safety aspects, air brake systems also contribute to the overall performance and maintenance efficiency of trucks. These systems can handle the demands of frequent and prolonged usage, reducing the wear and tear typically seen in hydraulic systems under similar conditions. This minimizes downtime and maintenance costs, allowing fleets to operate with improved reliability. Moreover, the adaptability of air brakes makes them suitable for a wide range of truck applications, from long-haul trucking to construction and emergency services.

Air Brake Pedals: Treadle Valves

Treadle valves play a pivotal role in the functionality of air brake systems by controlling the amount of air pressure applied to the brakes. As the driver presses the pedal, the treadle valve modulates the air pressure, providing precise control over the braking force and enhancing vehicle safety.

Functions

A key function of the treadle valve is to convert the mechanical force from the driver’s foot into an air pressure signal, which is then used to actuate the brake chambers. When applied, the treadle valve precisely adjusts the flow of compressed air to provide proportional braking force, allowing for smooth and controlled stops.

This modulation not only ensures that the vehicle can decelerate effectively without locking the wheels but also helps maintain stability and control during emergency braking situations. The reliability of the treadle valve is fundamentally important for maintaining safety standards in heavy-duty vehicles, making it one of the most crucial elements in the air brake system.

Key Components

The key components of a treadle valve include the valve body, diaphragm, spring, and plunger. The valve body houses the internal mechanism and serves as the connection point for the air supply lines. The diaphragm, located within the valve, acts as a seal to control the air flow based on the pressure applied by the driver’s foot. The spring provides the necessary resistance to return the valve to its default position when the pedal is released, ensuring a responsive braking system.

Finally, the plunger transfers the mechanical action from the pedal to the diaphragm, which adjusts the air pressure accordingly. Each component works in unison to ensure that the air brake system responds accurately and efficiently to the driver’s inputs, maintaining safe and reliable braking for heavy-duty vehicles.

Hydraulic Brake Pedals: Foot Valves

Foot valves are an integral component of hydraulic brake systems, often found in smaller vehicles. They manage the flow of hydraulic fluid to the brake calipers, ensuring effective and consistent braking performance.

Functions

Foot valves in hydraulic braking systems are the control mechanism through which the driver applies hydraulic pressure to the brake lines, thereby activating the brakes. When the brake pedal is pressed, the foot valve converts the mechanical force from the driver’s foot into hydraulic pressure by displacing brake fluid within the system. This increase in pressure causes the brake calipers or wheel cylinders to clamp or expand against the brake discs or drums, creating the friction necessary to slow down or stop the vehicle.

The notable advantage of this system lies in its ability to provide immediate and consistent braking response, offering a smooth and predictable deceleration experience. However, hydraulic brakes do not have a fail-safe mechanism to engage in case of pressure loss, making them less reliable in trucks.

Key Components

The key components of a foot valve in hydraulic brake systems include the housing, piston, seals, and return spring. The housing serves as the main body that encloses the other components and interfaces with the brake lines. The piston is responsible for creating hydraulic pressure by moving through the cylinder within the housing when the brake pedal is pressed.

Seals are crucial for preventing fluid leaks and maintaining pressure within the system, ensuring efficient brake operation. Finally, the return spring helps revert the piston to its original position when the pedal is released, allowing for the quick retraction of brake components so the system is ready for subsequent braking actions.

Air Brake Maintenance and Troubleshooting

Regular maintenance is critical to the longevity and effectiveness of air brake systems in heavy-duty vehicles. One fundamental aspect of maintenance includes inspecting the air lines for leaks or damage. Air leaks can significantly impact the brake system’s performance, leading to inadequate braking power or longer stopping distances. Additionally, you should check the air compressor’s performance and the pressure gauge readings regularly. The compressor must maintain adequate air pressure levels, and it’s vital to address any deviations from specified ranges promptly to prevent system failure.

It is also important to regularly inspect the treadle valves within the air brake system. You must check these components for wear and tear and any signs of corrosion or deformation. A malfunctioning treadle valve can lead to poor modulating ability, which could impair the driver’s control over the braking process. Replacing or repairing faulty valves can help prevent bigger issues that might result in costly repairs or even accidents.

In troubleshooting air brake systems, listening to unusual noises and paying attention to changes in braking performance can provide early indicators of potential problems. For instance, a sudden increase in the length of time required to stop the vehicle or a noticeable drop in braking efficiency might signify a problem with the air pressure supply or a leak in the system. Moreover, a feeling of softness in the brake pedal could suggest air in the brake lines or a defect in the treadle valve. In such cases, conducting a thorough system check and patching leaks promptly will keep the air brake system in optimal working condition.

Find Quality Braking Solutions at Van Horn Truck Parts!

Understanding air brake systems and what the treadle and foot valves do is essential for maintaining safe and reliable heavy-duty vehicles. Van Horn Truck Parts offers a wide range of high-quality truck parts, including air brake components, to ensure your fleet is always running at its best. Explore our selection of semi-trailer air valves at our online store today!